Sanitary Ware

Key Products for Sanitary Ware

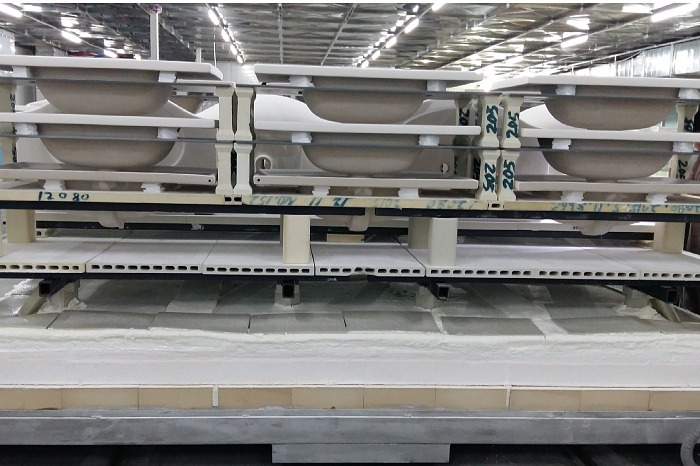

Sanitary ware requires precise shaping, glazing, and high-temperature firing to achieve strength, durability, and a smooth, hygienic surface.

The final firing temperatures can vary significantly depending on the type of clay, shapes, and glaze used, but they generally range from 2100°F to 2400°F (1150°C to 1300°C).

The firing process—typically carried out in tunnel or shuttle kilns—is critical for sintering the ceramic body and vitrifying the glaze. Kiln furniture, including setters, props, and batts, plays an essential role during firing by supporting the ware, ensuring uniform heat distribution, and minimizing deformation or glaze defects. The quality and design of kiln furniture directly impact firing efficiency, product quality, and energy consumption in sanitary ware production.

- SSiC Plate

- SSiC Support Tube

- SSiC Pillar

- SSiC Beam

- SSiC Burner Nozzle

- SSiC Roller

logo-300x127.png)