Powder Metallurgy & Magnetic Materials

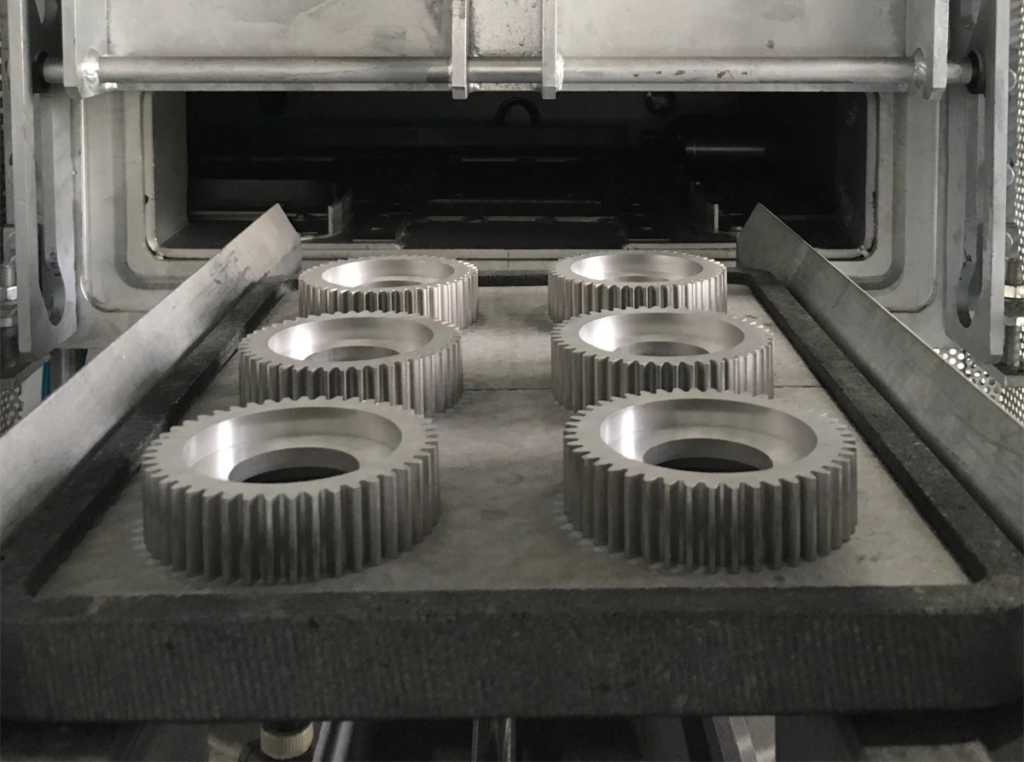

The typical powder metallurgy manufacturing process is made in three basic steps: mixture of the metal powder (including iron, steel, copper, titanium, aluminum, tin, molybdenum, tungsten, etc), die compaction, sintering, and additional heat treatment like surface finish.

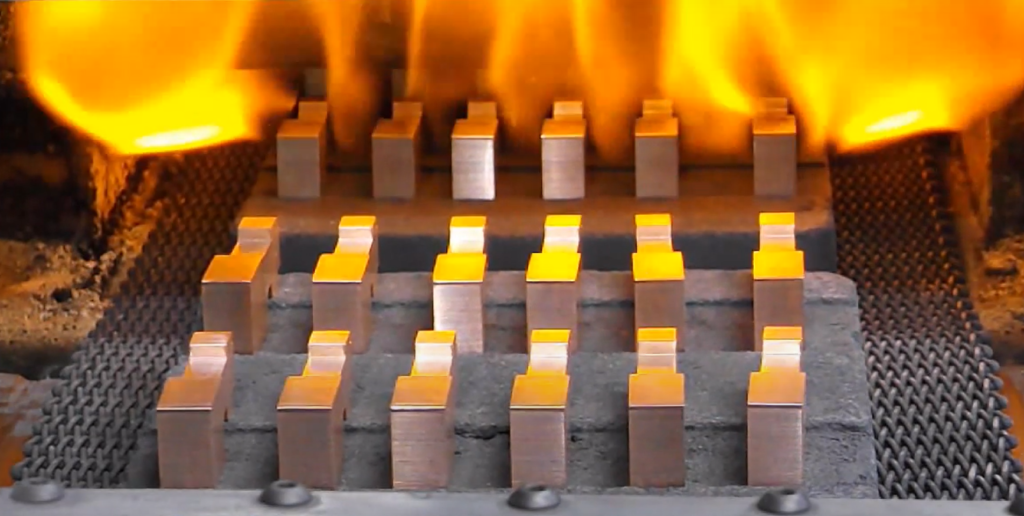

Sintering is a crucial step in the Powder Metallurgy (PM) process, where compacted metal powders are heated below their melting point to bond particles and achieve final strength and density. This thermal treatment is also essential in producing various magnetic materials, such as soft ferrites and rare-earth permanent magnets.

Sintering Temperatures:

Powder Metallurgy components: 1100–1400°C (e.g., steel, Fe-based alloys)

Soft Magnetic Materials (e.g., ferrites): 1000–1300°C

Hard Magnetic Materials (e.g., NdFeB, SmCo): 1000–1150°C (in controlled atmospheres or vacuum)

These processes often require precise temperature control, uniform heat distribution, and resistance to chemical interactions during firing.

logo-300x127.png)