其他信息

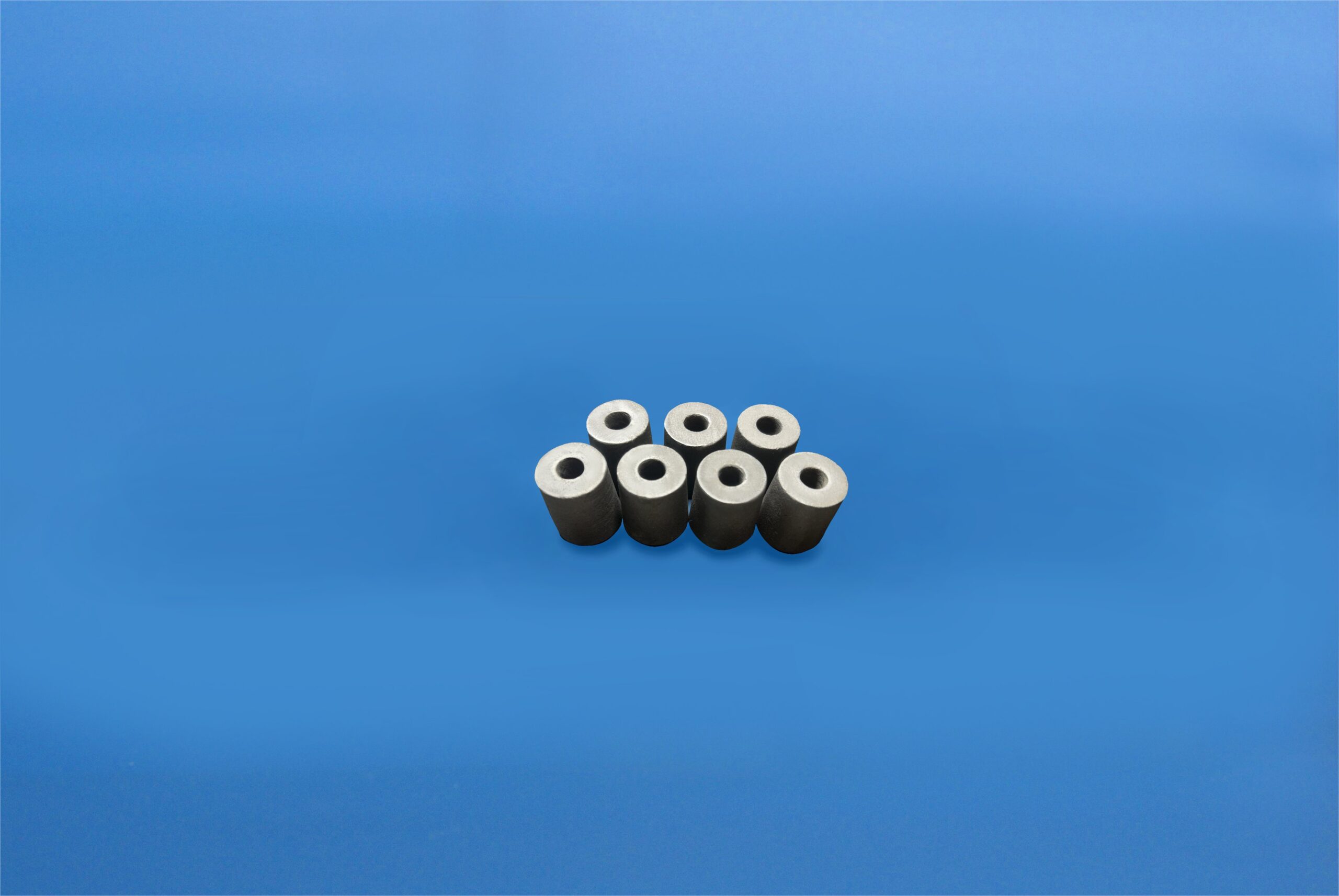

| Material | Reaction-bonded silicon carbide |

|---|---|

| Bulk Density | ≥3.02 g/cm³ |

| Apparent Porosity | < 0.1 % |

| Bending Strength (20℃) | 250 MPa |

| Bending Strength (1200℃) | 280 MPa |

| Elastic Modulus (20℃) | 330 GPa |

| Elastic Modulus (1200℃) | 300 GPa |

| Thermal Conductivity | 45 (1200℃) W/m.k |

| Thermal Expansion Coefficient | 4.5 ×10-6 •K-1 |

| Vickers Hardness | 20 GPa |

| Alkalinity and Acidity | Excellent |

| Max. Working Temperature | 1350 ℃ |

logo-300x127.png)