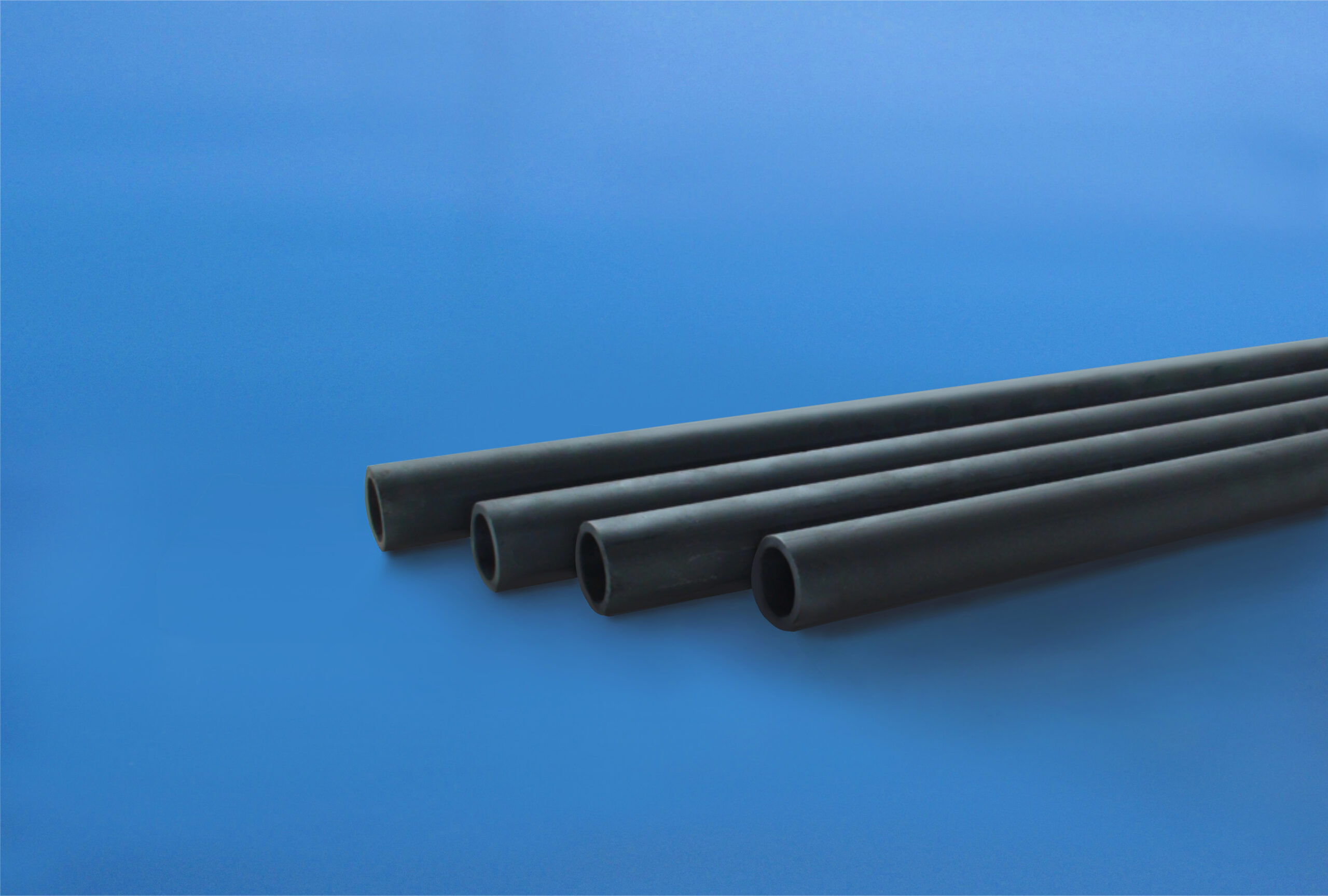

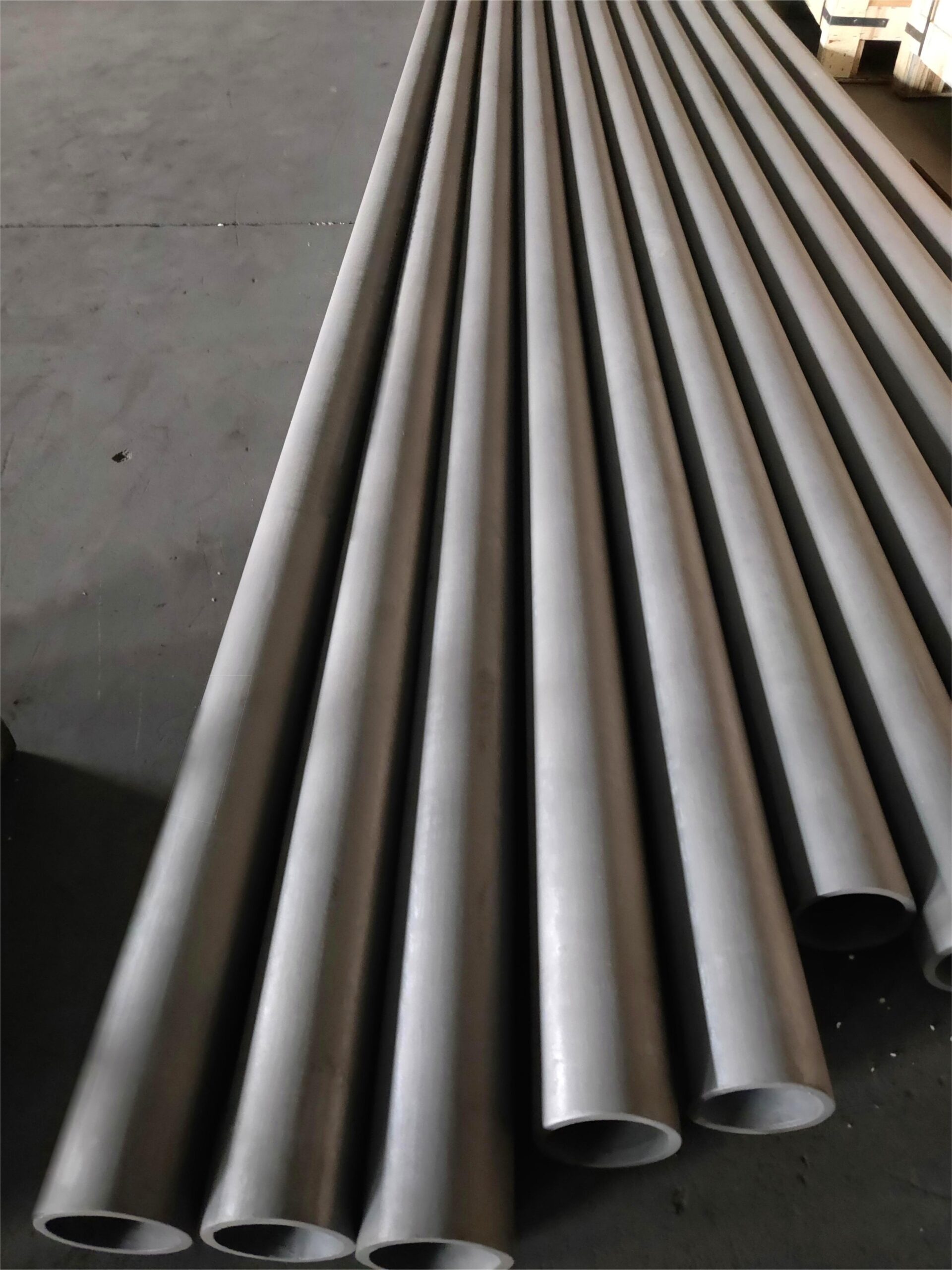

SiSiC Roller

Reaction Bonded Silicon Carbide (RBSiC/ SiSiC) rollers are essential components used in various high-temperature industrial applications.

Compared to traditional alumina rollers, their working life is 10 times more due to their high bending strength and no deformation after long-term use.

SiSiC ceramic rollers as the key part of roller kiln,its function is supporting and conveying calcined ceramic products under high temperature sintering process.The technical parameters of SiSiC ceramic rollers directly affected the application performance,quality and yield of calcined ceramic products.

Features:

Excellent high-temperature flexural strength.

Exceptional mechanical strength.

Excellent thermal shock resistance.

Good corrosion and oxidation resistance.

Dimensional accuracy and stability

Large bearing capacity in high temperatures.

No bend or deformation in long-term use.

Long service life.

Applications:

Lithium battery, ceramics, glass manufacturing, metallurgy, and thermal processing.

logo-300x127.png)