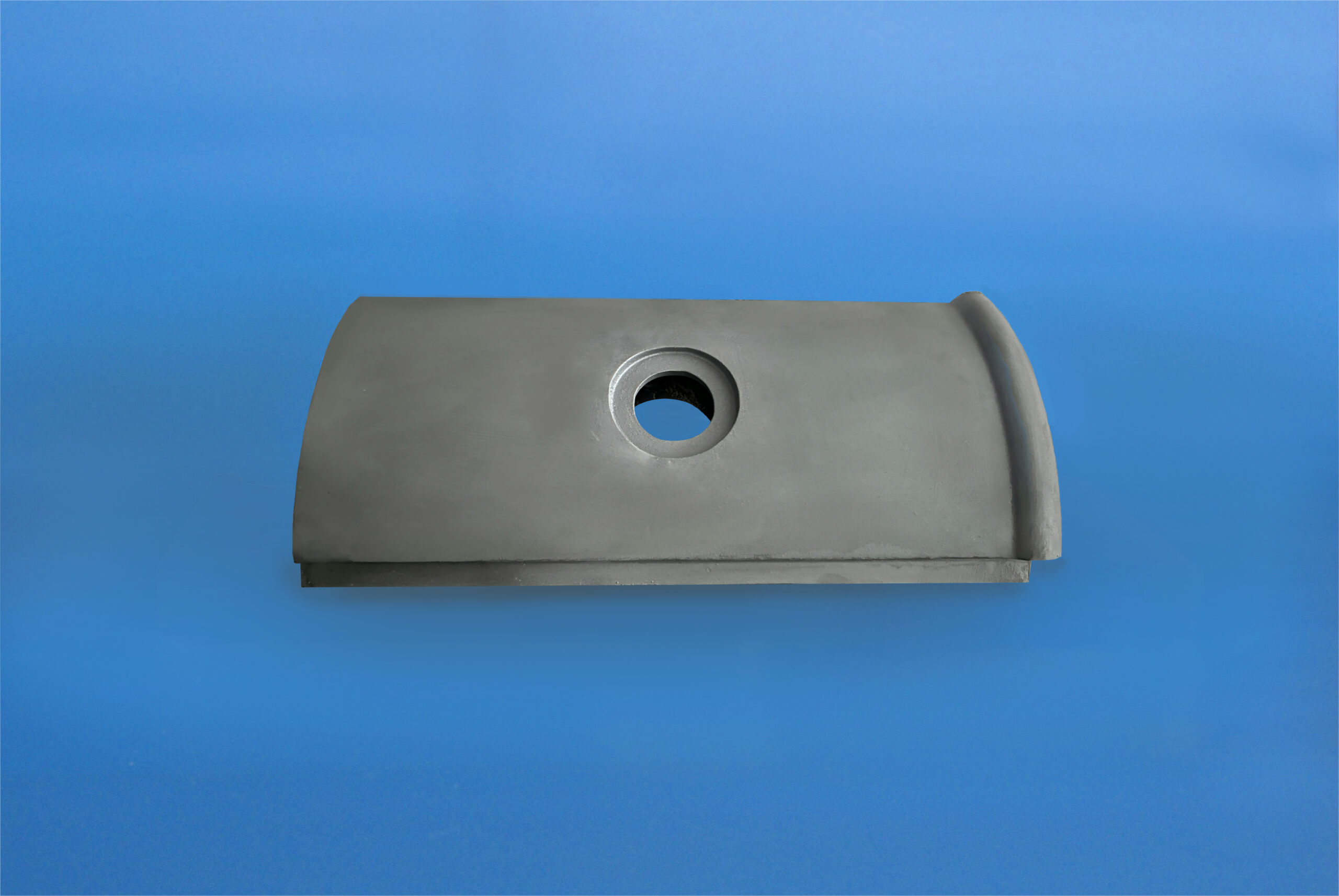

SiSiC Customized Parts

SiSiC (or RBSiC) customized parts are precision-engineered components tailored to meet specific requirements in demanding industrial applications. They are perfect for extreme applications where exceptional heat resistance, electrical insulation and chemical resistance are required.

Key Features:

High wear and corrosion resistance

Excellent thermal shock stability

Superior hardness and strength

Custom shapes and complex geometries are available

Stable performance in high-temperature environments

Typical Applications:

Kiln furniture and structural supports in high-temperature furnaces

Liners, beams, and rollers in the ceramics and metallurgy industries

Customized nozzles, guides, and flow control parts in chemical plants

Components for flue gas treatment and thermal power systems

Fastening components such as screws, nuts, and bolts

Ceramic, aerospace, automotive, electronics, semiconductor manufacturing, chemical processing, and other high-temperature heating industries.

logo-300x127.png)