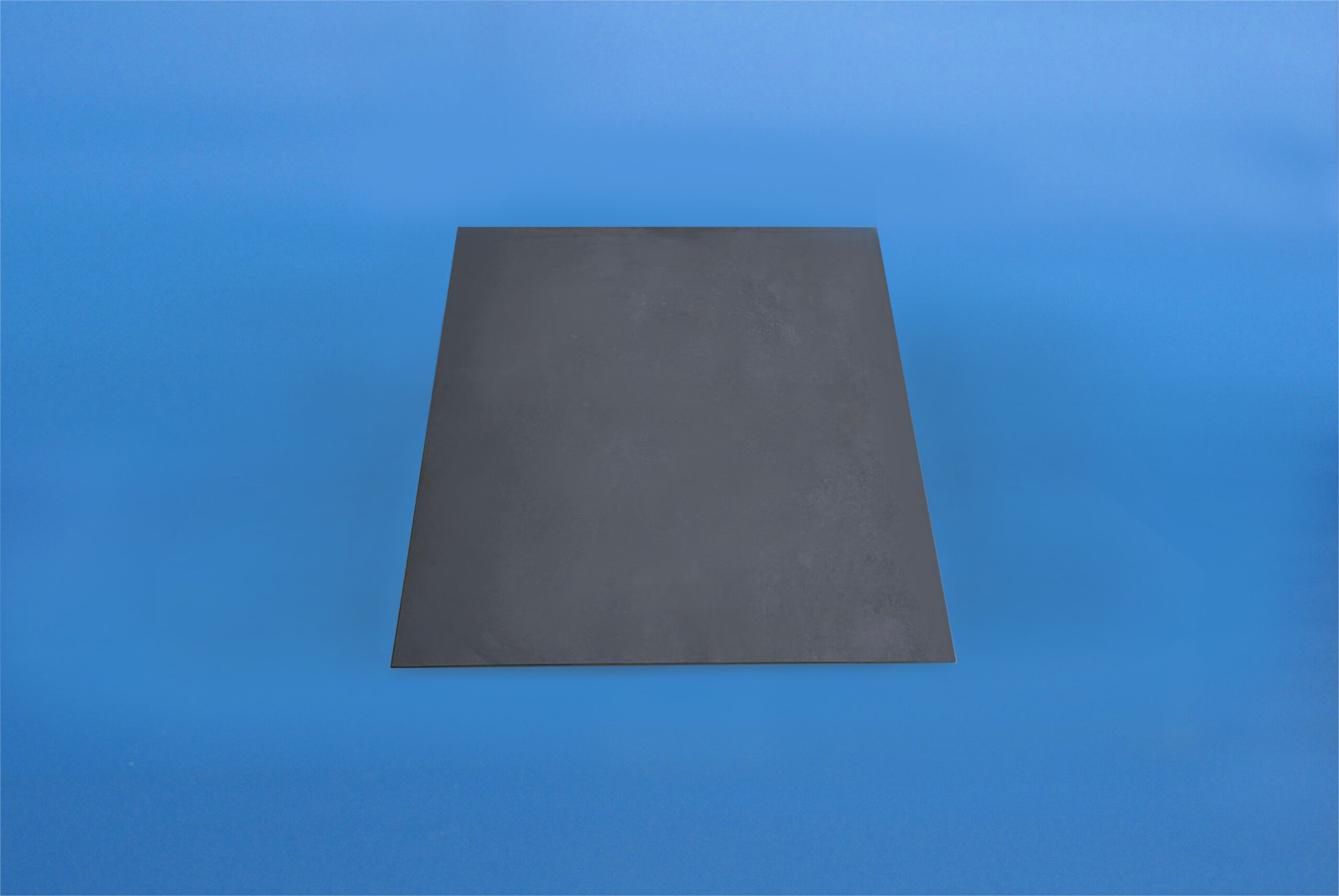

SiSiC Kiln Plate/ Batt/ Slab

Reaction Bonded Silicon Carbide (RBSiC/ SiSiC) kiln plates are made by combining silicon carbide (SiC) particles with silicon through a sintering process.

They are specialized components used in high-temperature industrial processes. Their primary function is to provide a durable and stable surface for supporting and heating materials within the kiln.

Features:

Excellent high-temperature flexural strength.

Exceptional mechanical strength.

Excellent thermal shock resistance and oxidation resistance.

Large bearing capacity in high temperatures.

Energy saving.

Applications:

The unique properties of SiSiC plates make them highly desirable for demanding environments where extreme temperatures, corrosive chemicals, and abrasive conditions are present.

Metallurgy, chemical processing, ceramics, glass, semiconductor manufacturing, aerospace, etc.

logo-300x127.png)